MAX: Mother's Automotive eXperiment

In summer of '06, we put a 100 mpg sports car on our things-to-do list. We moved quickly from "We could do this" to "We ought to do this," because we quickly convinced ourselves that such a car could be built on a Locost budget, and because it was pretty dang obvious by then that our world needs cars like this.

Of course a few folks said, "But what can one person [or "a teenie little company" or "you clowns"] do to make a difference?", but most folks got it, so I won't belabor our motives. And a very few folks said, "If Detroit can't do it, what makes you think Kinetic can?" and the short form answer to that is, because we want to and Detroit doesn't. So away we went. We bought a Kubota industrial engine that looked like it would be a good place to start, and dropped it in a Locost "book" chassis we keep around for just this sort of thing.

Mind you, we knew about the upcoming Automotive X PRIZE, but we were admiring it from afar and had no direct interest in it. A 100mpg sedan is beyond our budget, and possibly beyond our capabilities, and nobody was more surprised than me when the X PRIZE Foundation announced an alternative class for two-seaters.

The Challenge:

Design an build a practical, fun, affordable two seat car that gets great fuel economy.

"Design and build" are self-explanatory, but the other terms can use some clarification.

Practical as practical as the daily drivers of my youth, which included a Bugeye Sprite, a Karman Ghia, and a Triumph Spitfire. Nowadays I wouldn't consider such a thing practical if it was my only transportation, but nowadays I can afford two cars...and one of the above listed vehicles would still be practical for 9/10 of my current driving.

Fun ditto the list above. There are folks that say you can't have fun with two digit horsepower. I trust they've never spent a first date driving a Ghia down the coast to Big Sur, with the top down and a picnic basket in the trunk.

Affordable an economy car, not a space mission. Our somewhat arbitrary target is that it be buildable by a determined and well-equipped scrounger for $10k. That's in the range of a typical homebuilt sports car, though we know superduper fuel economy is going to be more expensive than superduper performance. Why? Because the wrecking yards are full of high performance powerplants just begging to be put into Cobra and Lotus Seven replicas, but high efficiency powerplants have to be bought new.

Two seat while most American driving is done solo, taking somebody else is common enough to call for a second seat. Besides, fun is funner when it's shared. For solo transportation, it's hard to beat a bike I built my first 100mpg+ street racer over 30 years ago; when most people weren't thinking about petrolium as a finite resource and gas cost me less than a penny a mile, but if you put good streamlining on a little bike, great mileage is what you get, whether it's what you're looking for or not.

For those who think two seats are too few, well, it was January of 2007 before I first saw a Prius with passengers in the back seat, and I'd been looking for years.

Great fuel economy I picked 100 miles per gallon, at freeway cruise speed. The science project vehicles that get thousands of miles per gallon by accelerating to 20mph and coasting down to 10mph, well, that's inspiring but it's not the problem solver. If our national speed limit were 35 and there were no hills on the roads, maybe our target would be 200mpg, but hey, in the real world 100mpg is a worthy goal.

Powerplant:

One of those real-world limitations is, it's not good enough to cruise down the freeway at 100mpg, you have to be able to get on the freeway without getting flattened; you need to be able to merge and pass and so forth. The secret to great mileage is low aerodynamic drag...

Well, hopefully the X PRIZE will inspire development of higher efficiency automotive powerplants, but if you want 100mpg at 55 miles per hour or better with current off-the-shelf internal combustion technology, you need to get your car's cruise power demands down to 8 horsepower or so, which...well, it isn't rocket science, you can do it and we can do it, it starts getting tough when you get much faster. But we could all be cruising along at 55 at 100mpg with 10 horse engines if we didn't mind taking six minutes to get up to speed, and dropping down to a trot when we hit a hill.

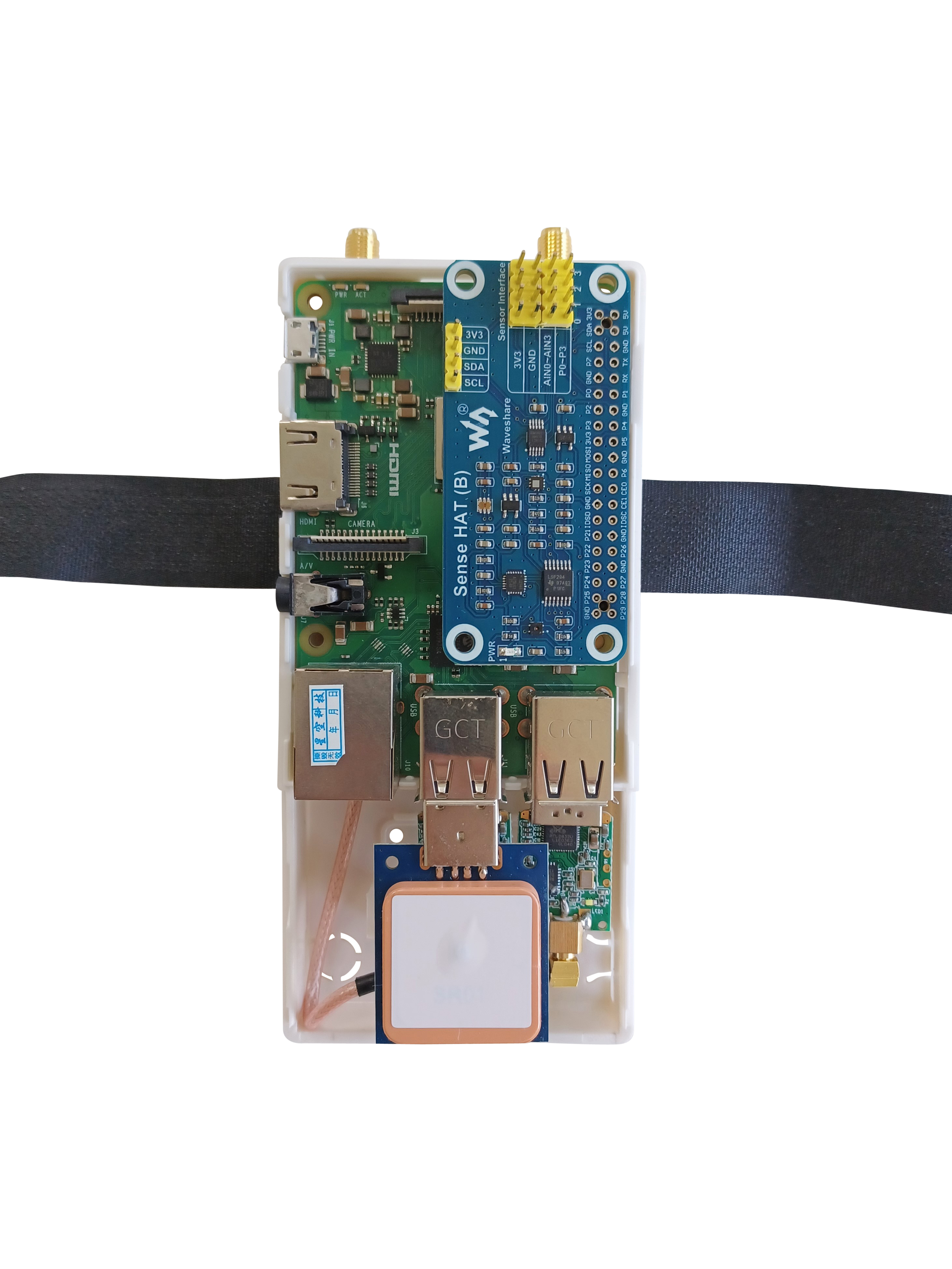

Light weight helps a bunch; it lowers rolling resistance, and acceleration and hillclimbing ability are directly proportional to weight (half the weight gives double the acceleration and double the grade), but still, some excess power is required. The problem is to find (or develop) a powerplant that has high efficiency in the 8 to 10 horsepower range, yet can crank out four or five times that power on demand. This 1100cc Kubota is rated at 32 horsepower and runs generators day after day at 50% power and high efficiency (.42 pounds of fuel per horsepower per hour), and though it's going to take a bit of tweaking to get the power range we want, it's a good basic engine to start with. The turbocharger is a big help, it adds a bunch of high end oomph without much (maybe not any) cost in economy at low power, and there are other off-the-shelf widgets that will further broaden the power range we'll keep you up to date as we work with them and who knows, maybe we'll invent something.

And maybe we'll have to, because one of the interesting features of the Automotive X PRIZE is a new standard for measuring fuel economy; a unit they call the MPGe. That's Miles Per Gallon Equivalent, using pump gas as a baseline. Diesel fuel has slightly more available energy per gallon than gasoline, so we (and the other diesels) need to get slightly better than 100mpg to reach 100MPGe. We don't yet know exactly how much, but the X PRIZE Foundation only dropped the green flag on August 1 and some details are still being worked out.

Streamlining:

Suitable bodies have been around for 40+ years; sports racers of the 1960s such as the Lotus 11 and Lola Mk1. Back then, small displacement racers couldn't meet their straightaway speed needs with brute force (having only around a hundred horsepower to work with) so streamlining was more important than downforce.

We may have to go the route of flowing lines and smooth transitions, but we were building a downforce body already for the 2k7, and with a few modifications, it might work well enough for a fuel sipping cruiser. The biggest advantage of the body style shown below is it will be relatively cheap to produce, since the bulk of the body is sheet metal (aluminum or steel) with simple curves no stamping or complex forming required. Fiberglass is a fabulous medium for relatively inexpensive limited production car bodies, but the key word is "relatively" and an all-'glass body would still cost a good four grand. Using fiberglass for fenders and nose, and sheet metal for everything else (including the hood; shown in red below for aesthetic reasons) could knock that cost in half.

I know some folks who make a fiberglass copy of a Lola Mk1 body, and I emailed Lola to ask if they'd mind if we used one for this project, but not surprisingly, Lola didn't respond. So one way or another, we're going tomake our own body, and it may well take us a couple of tries.

The first full-body fender parts have come out of the molds. Click here to go to the body design and construction log, you'll find photos on page 5. This is a forum with a bunch of other Locosters chiming in, it's pretty entertaining.

Sadly, my back-of-envelope calculations are pretty convincing that we'll need a roof to reach freeway speeds at 100mpg. Of course, I've been wrong before, and this body is already in progress, so we'll see how it goes with an open cockpit. But we'll probably have to bite the bullet and build a coupe, which means doors, windows, and other budget challenges.

(The body design and construction log link is courtesy of http://www.locostusa.com)

Sponsorships:

We are not seeking sponsors. The point we're making with our entry is, if somebody decides they want to drive a car that gets 100 miles per gallon, they can do so with available technology and a moderate budget. Besides, it wouldn't be fair to investors if we gave away our trade secrets, and that's exactly what we intend to do.

Our only sponsor and it's a mild enough sponsorship that it won't mess with our self-imposed moderate-budget restriction is a publication which has been guiding do-it-yourselfers on the path of &to quote their cover blurb, it's The Original Guide to Living Wisely, and they've been around for more than half my lifetime, and I worked with them on a couple projects in the '70s and '80s; they were great to work with then and we're delighted to be working with them now. They're Mother Earth News, and rather than them being concerned that our trade secrets might get out, well golly, you'll be able to read our trade secrets right there in their magazine.

I'm sure we could do 25% better if we had a million dollars behind us, but I'm confident that other entrants will have that end of the budget spectrum covered. Our interest is in what regular folk can do.

That said, there have been people and organizations interested in helping us out, and this will be a better car if we stop being such snobs about not-invented-here. If you build your own high mileage car, you too will have friends and associates offering volunteer labor, or saving you a few bucks by loaning you tools and whatnot, and these are resources not to be sneezed at. For donations of materials, we have some guidelines no strings attached (if your parent company wants a sticker on display, go to NASCAR) and whatever it is, it has to be available off the shelf and sensibly priced. "Off the shelf" means we're not going to demo your sodium guanolate battery technology, no matter how great it's going to be in three years, and "sensibly priced" means if your ultra-low-rolling-resistance tires cost more than regular tires, they need to pay for that difference at the gas pump.

For volunteer labor, we're wide open. If you can weld, or turn wrenches, or paint things, and can put in half a day some weekends, man, we'd love to have you here. If you can design chassis, bodies and/or suspension better than we can (and it's no great stretch), well heck, you can telecommute. The only limitations that come to mind are: A) no trade secrets if you come up with something that improves the car, our readers get to read about it, and B) if you're here and in the way of a camera, we'll want you to sign a model release.

The Process :

August '07: Our first engine modification was to replace the upright thermostat cover with a cover that lets the hot water exit horizontally, which will let us make the hood a couple of inches lower--as it was, the water outlet was the highest point on the engine. We installed a new oil pan and oil pickup (which fits inside the oil pan and sucks up the oil) to improve ground clearance...unless we decide to get all sporty and lower the engine some more. The standard pan, with bottom drain plug, hung 2" below the chassis; this one is about 3/8" below the chassis. About half the height savings is because the pan is shallower, and the other half comes from its front drain tube. For oil changes, we'll probably park the car a bit nose-down.

I'll do some head-scratching before making a final decision on engine height--but that's what this "mule" is for. Before this driveline makes its public debut, it'll go in a pretty chassis, but it's sure nice to start with a mule. Since we don't have a wind tunnel, we may never really know if the aerodynamic benefits of a smooth belly will be worth the weight of a full-length bellypan, but that's one option; you can barely see the bottom of the oil pan (below) and it wouldn't make much of a dip in a bellypan.

All engine parts are straight off the Kubota shelf. For anybody who wants to duplicate this setup, the part numbers for the engine and these mods are listed at the bottom of this page.

September '07: We've selected a donor car for the driveline and suspension components; it's an early '80s Toyota Corolla wagon that has had a hard life in general, and sea spray in specific. We call it the Corrode Warrior.

Any rear wheel drive Corolla would do for our needs; the major components are pretty light (the five-speed overdrive transmission and the rear axle are of particular interest) and they were among the most common cars in America for about a decade...and that decade was a while ago so they're pretty dang cheap.

This one is particularly cheap, and though it was a perfectly functional automobie...

Okay, not "perfectly" functional, but if you didn't mind being rained on (the roof had actually rusted through) and had had a recent tetnus shot, and were fairly thick-skinned about comments from spectators ("Was the body still in it when they dragged it out of the lake?"), well, it still ran. It was capable of getting to the crusher under its own power, and that was where it was headed before it touched my heart.

You see, I'm a huge fan of use-and-reuse as a principle of conservation, and from an environmental standpoint, taking an existing item and using it over again is generally superior to making a new one. So as a matter of principle, we chose a car that was otherwise doomed to destruction. And as a matter of whimsy, it'll be fun to make a silk purse out of a sow's ear.

Now then, adapting the Toyota transmission to the Kubota engine is particularly challenging. Fortunately the flywheel is slightly recessed into the Toyota engine block, and the flywheel on the Kubota is slightly raised, so there's room for an adapter. Making this adapter took some time, but it came out looking good in sandcast aluminum.

Engine side

Trans side.

Trans side.

Whittling the casting pattern took the most work (if you don't count measuring and scheming as work; a metrification service did the measuring and I did the scheming), but as the rocket scientists say, it ain't rocket science. I used three layers of 3/4" MDFB (medium density fiber board), a band saw, and a variety of sanding devices (particularly a reciprocating spindle sander), but it could have been done with a saber saw and a sanding block. After the individual layers were finished, I screwed them together with sheet rock screws and gave the assembly a quick coat of rattle-can Kilz to seal it.

I had a local foundry pour the part;they took my pattern, put it in the middle of a box, pounded sand on both sides of the pattern, took out the pattern, put the two halves of the box together and poured molten aluminum where the pattern used to be. Then I built a clamping plate for the raw castings and took it all to a local CNC machine shop, where we translated the x and y coordinates into G Code, and in only two tries, had a bolt-on engine adapter for the Toyota T50 transmission. The experience left me more sympathetic to the commercial engine adapter companies.

Because I made the pattern by hand and had the adapter plate cast instead of machined out of billet, it's not a practical part to open-source, so we're keeping the price down...down around the price of a post-Cash For Clunkers rear wheel drive Corolla.

The other adaptation challenge was to find a clutch disc that fit the Toyota trans input shaft spline on the inside, and the Kubota flywheel on the outside, and a pressure plate that would fit the aforementioned disc and match up with the Toyota's throwout bearing plus bolt to the flywheel without drilling and tapping new holes in the flywheeel, and the final thickness of the cast adapter plate would be determined by the thickness of the disc/pressure plate combination...I was indeed fortunate that some local clutch professionals (Clutch Doctor in Eugene, OR) took an interest and let me hang out with them all day, with my flywheel in one hand and digital calipers in the other. We found a disc from another model Toyota and a pressure plate from, of all things, a Suzuki Swift, that went together just slick. There are lots of aftermarket suppliers of these parts, so instead of part numbers, we'll give model numbers.

Here's the parts list to date:

Engine: Kubota D-1105T

90 degree thermostat cover: Part #1G25373260

Oil pan: Part #17523-01500

Oil pickup tube: Part #16261-32117

Transmission: Toyota T50 (five-speed rear wheel drive tranny from early Corolla, among others)

Clutch disc from 81-88 Toyota Tercel DLX or SR5

Clutch cover (pressure plate) from 89-91 Suzuki Swift, 95-97 Geo Metro Lsi, or 89-01 Suzuki Esteem (e.g. Exedy SZC 509)

November '07: We know we've gone down a rabbit trail here, but we just couldn't stand it. It's one thing to have have confidence that a concept is sound hey now, what could go wrong with dropping an industrial diesel into an automobile and another thing to do it and drive it. So after looking at the Corrode Warrior for way too long, we realized our powerplant and driveline proof-of-concept was right in front of us; we yanked out the Toyota engine and put in the Kubota.

Sounds pretty easy, doesn't it? It was a little harder than that. The standard engine sits awfully close to the front crossmember; it's a fairly long engine so it has a fairly long oil pan; the oil pan is about flush to the engine block in the back half, for crossmember clearance, and deep in the front half for sufficient oil capacity. To get the needed clearance and capacity with the Kubota, which is a significantly shorter engine end-to-end than the stock fourbanger, we had to move the engine forward several inches as well as notch the oil pan.

For some mysterious reason, the Corolla chassis has a second set of internally threaded transmission mount stations about 4" forward of the standard mounting points. Rather than look a gift horse in the mouth, we let that distance determine how far to move the engine, and had a driveshaft made to fit. We made a pair of custom motor mounts, cut the oil pan to fit and welded in a 16 gauge mild steel patch, welded a tractor muffler (complete with rain flap) to an exhaust flange, and from there it was just a few odds and ends (a low pressure electric fuel pump, an in-line fuel filter and an air filter on a snorkel, some ridiculously easy wiring, a muffler port in the hood, etc) and we were off and running.

Perhaps "running" is a bit overstated. It was more of a stroll, really. With 32 horsepower in a car that, with me and a flight engineer on board, weighed a good 3200 pounds that's 100 pounds per horsepower, which is well within the range of a serious bicyclist for a short spurt. I soon learned to shift at 3000 RPM, which is where the governer kicked in, and the car stopped accelerating. In top gear, the governer kicked in (or is it kicked out?) at 67 mph indicated, whether going uphill, downhill, headwind, tailwind...sort of a Good Citizen Cruise Control.

We learned a lot from this test; enough to make it worth the trouble. Some of what we learned could have been calculated (for example, we're going to need a taller final drive ratio if we want to go faster than 67 (which we do) but some of it needed to be learned from experience (the clutch pedal "feel" is good, and the engine, though lacking in horsepwer, has gobs of torque, so there's no problem when pulling away from a stop sign on a hill, or a stop light in traffic). But we're not going to learn much more from the Corrode Warrior; we need to decommission this car pretty soon so we don't get attached to it. In its own weird way, it's kinda fun to drive, and if they ever make another Mad Max movie, boy, have we got a deal for them.

Our next purchase will be a rear axle out of an automatic transmission Corolla; those had a bit taller rear end than the stick shift models, so we have wrecking yards to explore.

March '08: Man, it was a long and slow winter. We put the Kubota back in the Locost chassis, finished up the suspension, and got some of the subsystems worked out (a parking brake, for example) but mostly we just survived. On the bright side, we didn't squander any fossil fuels trying to make the place warm. The Corrode Warrior went to the crusher, to be recycled into other cars ashes to ashes and rust to rust. We're ready for the sun to come out, I'll tell ya.

Oh yes, one other thing. Over the winter, we came up with a cute name for the project. It's called MAX now, short for Mother's Automotive X Prize

April '08: Sunday the 6th, MAX was ready for its first weight-on-the-wheels, sit-in-it-and-make-motor-noises photo...but I didn't have anybody around to help me get it off its platform (or take a photo) so I mounted the radiator instead. Monday morning a couple friends came over; it quit raining so we decided to push it out and take pics in the sunlight...Oregon in April, it could have been a while before our next sunbreak..but the shop is about two feet higher than the pavement so we knew it was going to be a hassle to get back inside...

Anyway, to make a short story short we figured we could plumb and wire the powerplant quicker than we could hook up a comealong. I did the fuel system (a 1-gallon tank, two bungee cords and the pump/filter/fuel line from the Corrode Warrior), my friend Dave did the electrical system (a toggle switch and two pushbuttons--the toggle for the fuel pump, one pushbutton for the starter motor, one pushbutton for the glow plugs) and mounted the buttons on a scrap of wood (and mounted the wood to the chassis with a C-clamp). We pushed it out on the porch and fired it up and really, it was that simple. Our secretary Jacky hopped in where the passenger seat will go someday and off we went.

This is probably a new record from rollable to driveable--about an hour and twenty minutes There's no other plumbing yet (the parking brake handled the stopping chores) and no other electrics (lights will come when there's a body to bolt them to) and it's nowhere near legal or even sane, but we have very little traffic around here and no visibility restrictions...and with only 32 horsepower, how much trouble could we get into?

In retrospect, I think we could probably have gotten into plenty of trouble. It's an exciting little car, and from a seat-of-the-pants standpoint, it doesn't seem lacking in horsepower. The low-end torque is admirable, and after half a dozen starts we quit using first gear starting in second saves a shift and it gets off the line smartly that way. We were having too much fun for a car that accelerated faster than it stopped, and man, it corners great, but we really shouldn't have been pushing it like that before getting it a bit more finished...so after an hour or so, we parked it 'till it gets brakes and seats and belts and rollbar. But it goes all right and it's going to be lots of fun.

April '08 (continued): More puttering around. We got the brakes plumbed; using parts from the Corrorde Warrior and three new brake lines from a local auto parts store; the only problem is the rear brakes lock up a smidge before the front brakes. I doubt it will be an actual problem in actual driving, this thing stops pretty dang quick, but it would be a nuisance on a race track...what am I saying, it's a 32 horse economy car, why am I thinking 'race track'? Because it feels like a race car, that's why; admittedly a vintage racer but a race car nonetheless.

It may feel less racy when it gets more comfortable at present, the interior is what the auto journalists call "spartan" but I think it will always feel vintage. At present, the interior isn't particularly differentiated from the exterior, and the vintage feel is circa 1912, which might be overdoing it a bit. I think we can bring it up to the '50s without much difficulty; we can replace the lawn furniture bucket seat with a bench seat and give it period lighting; things like that.

Note the New, Improved exhaust system. Keen observers will note the muffler: there ain't any. It's an 1-1/2" straight pipe with a few bends, but no baffling at all. I was a bit surprised by how quiet it is, but I probably shouldn't have been. First of all, the turbocharger is pretty effective at extracting power from exhaust gas pulses, and by the time the pulses get through spinning around they're dazed and confused and lack the energy to make much noise. Second...you've heard high horsepower cars making noise on purpose, right? They sit at the stop light going rumbarumbarumbaBWAAArumbarumbaBWAAA. The BWAAA part is when the driver steps on the gas. Now imagine how they'd sound if the gas pedal only went down far enough to make 32 horsepower. All you'd get is a feeble lower-case bwaaa between the rumbarumbas. I can, quite literally, put it in neutral, push the throttle all the way to the floorboard, and have a normal conversation with someone standing next to the car.

That muffler we were using last week, the one that stood straight up? I'm sure it would take the bark out of a non-turbocharged engine, but it's nothing fancy. It has a perforated tube inside, and some fiberglass packing around it, and that's all there is to it; if you dropped a golf ball in one end, it would come out the other end with nary a clank. That muffler has style, though, and we're not throwing it out. We're saving it for state fairs and tractor pulls.

April '08 (last Sunday of the month): We got the three main body parts mounted this weekend. The nose and scuttle are our TTL parts and the hood is old CMC stock. Our local high school colors (go Cougars!) are red and white so we'll most likely stick with variations of this color scheme.

This is less than ideal aerodynamically, but at least it's obviously a car now. We'll continue with the Lotus Seven look to get it registered, we'll put on enough miles to get a mileage baseline, and then start adding and testing aerodynamic improvements. We did a nice job on the fiberglass installation, the scuttle and hood (oh all right if you insist, "bonnet") are held on with two Dzus fasteners per side, and the nose has hinges on the front and the hood holds it down in the back. Clean and simple, no more fittings than necessary and we can get to the radiator without opening a tool box.

May '08: Got the body panels installed (and wrote a tutorial), got the lights lit and the plumbing plumbed; we're ready for show-and-tell at the DMV.

June '08: Boy, plans can change all of a sudden.

The fine woman at the DMV declared MAX a car, we got it registered and drove around locally for a hundred miles or so. It still needed some finishing touches--a roll bar, for example--but hey, that's no reason to delay driving, right? Especially on a beautiful second Saturday in June, with the beach just an hour away down a twisty canyon road. Besides, I wanted to find what kind of mileage MAX got when pushing it hard...all the reason I needed for a charge down the coast.

Above is the last pretty picture of MAX on the road. Dave Levison, who has helped us hugely in the assembly process, took this photo from his Miata as we zipped down Highway 199. When we hit 101, he headed north to Brookings and I headed south into California, hammering the throttle with wild abandon and generally reliving my misspent youth. At the hundred mile mark I pulled over for a fuel consumption check (where an attractive woman said "Wow, cool car!" and her husband took some photos of her and MAX and me, to prove you don't need 300 horsepower to get a wow from a pretty gal...more later when I get permission to post a pic) and found I'd burned a hair under two gallons, and boy was I happy. 50-plus miles per gallon and I'd been pushing it hard; add streamlining and slow to 55 and we'll have 75mpg in the bag.

I was thinking about safety (note the headlights are on in the photo above) but not thinking too hard, it was just too nice a day. It was so nice I wasn't even annoyed to be stuck in traffic when I reached Euraka, stopped behind a van that was waiting for some pedestrians to cross the street, and BAM I was accelerating toward that van at normal traffic speeds and WHAM upon contact with the van, I again came to a full stop.

It happened so fast, it was over before I was aware I'd been rear ended. It's probably a good thing I was there, because if the sedan behind me had hit the van in front of me, without MAX acting as the creamy filling in that automotive Oreo, it would have driven the van into the crosswalk, and we'd be talking human tragedy instead of property damage, but MAX is totalled.

We'll be building a replacement of course, and there are lots of reuseable parts (the engine suffered some cosmetic damage up top, where the nose got jammed into the turbo, and it's going to need another oil pan, but it's otherwise good to go), and we have the best possible connections for spares (we make most of them) but this is going to waste a month we don't really have to waste.

I must say, the insurer of the driver who hit me is right on the job. Once I got through to them, they assigned me a claims adjuster, who googled "x prize" and immediately understood why we're in a hurry to settle this thing. He got an appraiser out to us the next Saturday morning (his professional opinion: yep, it's totalled) and he's expediting the process on his end and seems to truly wish us well in this project

Augist '08

I skipped a whole month of update. Too dang busy. Having our demo get crunched sure threw off our schedule. Plus I'm a double-blogger now, doing MAX Updates for the Mother Earth News website--if you click here you'll find something new every week.

Here's where the new car stands today. It's as much like its predicessor as possible, except for the rear axle. It was waaay back in November I said "Our next purchase will be a rear axle out of an automatic transmission Corolla" so since the other axle got killed in the crash, we've put in a 3.30 from an automatic. We should know how it works by mid September.

The insurance thing got settled; the medical part is floating around, as those things do, but the car part is squared away. They paid a little more than they might have liked for the total, we paid a little more than we liked to get the wreckage back, it evened out. We're covered for the costs, but not for the three months it's taking to get back up to speed. Yes, this is our top project, but it's not our only project, and MAX comes second to shipping orders out and paying our bills.

Still pretty busy, I let another month slip away on this page, but I have kept up my Mother Earth News MAX Upadate blog, so you can still get your weekly fix.

Since I last posted here, we finished Son of MAX and gave it an alternative fuel supply. Thanks to the generous support of PlantDrive.ca and PlantDrive.com we converted the car to run on straight vegetable oil as well as diesel or biodiesel. We gussied it up to look like the Lotus 7 in the opening credits for The Prisoner and entered Escape from Berkeley, which was an amazing no-petroleum-allowed alternative fuel rally (no, Officer, we're not racing...it's just that whoever gets there quickest wins all the money) from Berkely to Vegas. We named our team the Prisoners of Petroleum, Sharon Westcott hopped in the navigator-slash-riding-mechanic's seat and we lashed a week's worth of clothes and camping gear on the back. We headed south down the coast to the start line at Shipyard Labs, with a stop at Bert and Fay Curtis's place to pick up some "clamshell" fenders (which I must admit I'd always thought of as an affectation, but hey The Prisoner had them and we were stylin')--Bert and I worked all night installing them, and Sharon and I arrived at Shipyard Labs that evening. Man, I am too old for this all-nighter stuff.

Next day while I napped, Sharon gave the fenders a hit of British Racing Green (or as it said on the rattlecan, "Green"). Next morning the race...I'm sorry, I mean rally, rally...started, with media coverage all the way from Geek Entertainment TV through The New York Times; then it was up mountains and through passes and across deserts and a grand adventure I'll have to write up some time soon, ending at the Sahara three days later.

Well big surprise--we won it! That's Sharon holding our time sheet folder aloft as we pulled up to the finsih line. More publicity, more press, and since we had proved ourselves worty of more attention, The NYT featured us more heavily in their update story. The pre-race favorite (I mean pre-rally favorite) was The Green Team, driving a wood gasifier powered V-8 pickup. They had it down, I'll tell you--a team of six (two in the truck, four in their chase vehicles), lots of spares (including an entire spare truck on a trailer), sponsorship from Auburn University, and they'd run the course already (backwards, on their way to Berkeley from Alabama). The Green Team had a slight lead on us at the end of the first day, but that night a snowstorm closed Tioga Pass and they had to reroute us for a few hundred miles, and about half of those miles were river canyon roads and...man, we were smokin'! Seriously, despite our modest horsepower MAX was moving out. We were passing sport touring bikes, the folks we passed were giving us the thumbs-up, sport riders coming the other way gave us cop-ahead warning flashes--we were 32 horse hooligans, I'll tell ya. By sundown we had a substantial lead.

On the road we saw our first NYT article, it was a fun read and pretty accurate, though it did claim...

Jack ... said his roadster could go 72 m.p.h. — and get 70 miles to the gallon — using nothing but vegetable oil.

...which was a bit of an overstatement. In its present trim, MAX can go 72 mph OR get 70 miles to tha gallon, but it can't do both at the same time. With streamlining I'm thinking we'll be able to do both (70 at 70) but for now the formula is roughly (mph + mpg = 120). We can get 70 mpg at 50 mph, 60 at 60, 50 at 70, all the way up to...well, all the way up to 71-1/2 mph, which is where the 3000 rpm governor kicks in.

At the awards ceremony, we got a large commemorative poster, and even better, a large commemorative check, which we traded to the bank for five grand. ka-CHING! Not a bad competition debut, eh? We're the favorites now, the team to beat at Escape From Berkeley II, where we'll rally (is that a verb? at least I didn't say "race") from Berkeley to Mexico.

One last thing. We took it easy on the road home, but only kinda. Since the snow had melted on Tioga Pass, we decided to see how MAX would handle the high altitude, and crossed at 9987 feet, trouble-free, leaving a trail of french fry fumes behind us.

We stopped at a viewing point overlooking Yosemite Valley. That's Sharon with her back to the camera, looking at Half Dome. And what has the attention of every other person in the parking lot, including the guy running the paint striping machine? Yep, MAX.

I just love this picture. When the crowd started gathering, I stepped back and 'click'. I wish Ansel Adams had been there, rest his soul.